The capabilities of 3D printing are evolving quickly. From laboratory to space applications, 3D printing has found its way to transform today’s industries. As more industries adopt the technology, more materials are also being explored to be utilized in 3D printing, symbolizing a new age for manufacturing. It is now possible for other companies and industries to use additive manufacturing in areas they were previously unable to do so. More on 3D Construction Printing in Parola Analytics 2023 Technology Trends Report.

In this article, we looked at recent patents and patent applications in 3D Printing.

Diamond Age 3D, Inc.

US 11,536,019: Wall system with novel structures and method of construction thereof

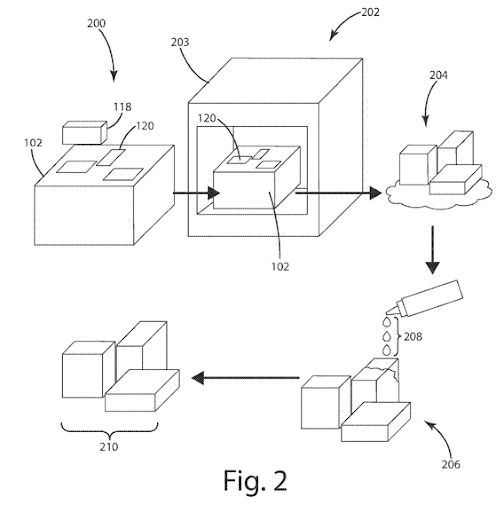

The ‘019 patent relates to a method of constructing unique wall systems using a 3D printer apparatus. Known 3D printers that are currently used typically use a mixture of grout and mortar as raw materials for the construction. Because of the mixture’s low viscosity, each layer may result in “bulging” while printing, which may be undesirable in certain construction projects.

To overcome the issue of “bulging”, the ‘019 patent uses thicker and stiffer concrete mixtures as feed to the 3D printer to create inner and outer wall panel layers. To create the wall system, a concrete foundation is formed with vertical and horizontal reinforcements. This is followed by incorporating the 3D printed wall panel layers. Each horizontal layer is printed over another layer until it reaches the desired height of the system.

U.S. Patent 11,536,019 was filed on May 20, 2021, and was granted on December 27, 2022 to Diamond Age 3D, Inc. Diamond Age is a startup company that automates construction and integrates 3D printing to building houses.

In March 2022, it was reported that Diamond Age was able to raise $50 million to scale up its robotic 3D printing construction system.

UT-Battelle, LLC

US 11,538,597: Additive manufacturing of composite neutron absorbing components

U.S. Patent 11,538,597 was filed on June 29, 2020, and was granted on December 27, 2022 to UT-Battelle, LLC. UT-Battelle, a partnership between the University of Tennessee and Battelle Memorial Institute, manages and operates the Oak Ridge National Laboratory (ORNL) and is responsible for delivering the U.S. Department of Energy’s research mission at ORNL which includes innovations in technologies involving nuclear energy generation.

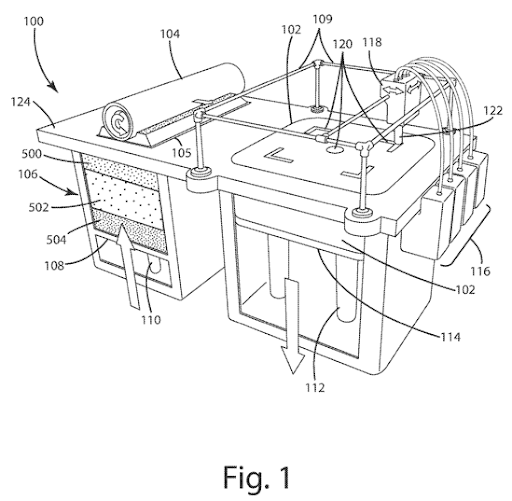

The ’597 patent relates to a method of 3D printing composite neutron absorbing collimators from different materials. Neutron collimators are typically found in nuclear reactors and are devices used to reduce background radiation. Neutron collimators use neutron absorbing materials that are usually composed of a single material due to easy manufacturability. Through additive manufacturing, it is possible to have a collimator with two or more different materials.

3D printing of neutron collimators is not exactly a new method. In 2018, UT-Battelle filed for a patent (U.S. Patent 11,404,180) on 3D printing collimators of a single material. The ‘597 patent is an upgrade of this method in that it uses a powder printing process that can produce collimators of at least two types of materials. The powder printing process outperforms the fused deposition technique of Anders Olsson and Adrian R. Rennie which can only be applicable on pure thermoplastics or thermoplastics combined with other materials. The ‘597 patent can print a wide range of materials.

The upgraded method utilizes a binder jet printer where a first powder made of a specific material is dispensed to create a first portion of a powder bed and binding it with a binder to produce the first component of the neutron absorbing composite. The process is repeated if more types of materials are formed into the composite.

Neutron absorption is essential for safeguarding people and the environment from nuclear reactor background radiation. The ‘597 patent will be useful in scaling up the production of neutron absorbing components.

The Boeing Company

US 11,542,041: Additively manufactured satellite panel with damping

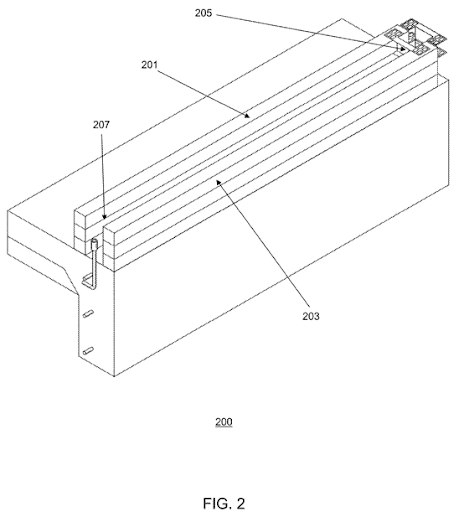

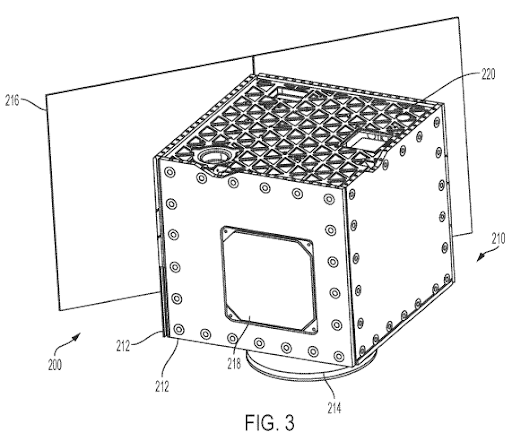

The ’041 patent relates to a system of additively manufactured satellite panels. Conventionally, satellite panels are built using different components attached together. Such construction is favorable because it provides excellent structural damping which limits the adverse effects of vibrations upon launch of the satellite in space. The rising cost of this method, however, prompted the shift to 3d printing the panels which led to a novel design of the panels along with a new method to manufacture them.

The satellite panels are built by 3D printing of wall panels which include a facesheet and stiffener. Depending on the function of the panel, stiffeners can be found in either the inner or outer side of the facesheet and can be printed in any shape. A damping layer of viscoelastic material is applied on the flange portion of the stiffener on the wall panel to provide the desired vibrational damping that was naturally occurring in conventionally constructed panels. While the facesheet and stiffeners are composed of strong and lightweight metals, the damping layer is composed of heat resistant elastomers. With this, the printed satellite panel can endure the conditions associated with the launch and operation in space.

U.S. Patent 11,542,041 was filed on May 18, 2020, and was granted on January 03, 2023 to The Boeing Company. The Boeing Company is an aerospace company known for their commercial airplanes and jetliners, defense products and space systems. In March 2022, Boeing announced their use of 3D printing to accelerate the production of a Wideband Global SATCOM or ‘WGS’ satellite for the U.S. Space Force.

More insights on 3D printing technology in our 3D Printing Landscape Report.