The share of solar in the global market for energy generation has doubled in the last 5 years and continues to see rapid growth [1]. While non-renewable energy sources dominate the charts, solar power holds the largest share in the clean energy sector at roughly 44% [2]. Four decades of research has produced the most widely-used solar technology at present: silicon solar cells [3]. Roughly 90% of the solar panels used today are made of silicon. You see them everywhere—from residential and commercial rooftops to solar farms, even on NASA’s International Space Station and space telescopes. Silicon has been a material of choice because of its versatility in different applications and the good balance it provides in terms of performance and durability.

One of the main issues with solar cells is that they’re highly inefficient. The best performing commercially available silicon solar panel so far has a power conversion efficiency of only up to 22% [4]. This means that only less than a fourth of the light striking the solar panel is absorbed by the cells due to limitations imposed by various factors including climate conditions and the nature of materials comprising the solar cells. Although, this conversion efficiency is already relatively high compared to other cell types, production cost presents another major difficulty. It takes approximately 14 kW-hours of energy to produce a kilogram of metallurgical grade silicon [5]. Silicon panels also tend to be rigid and bulky, making them only suitable for large-scale application.

One of the main issues with solar cells is that they’re highly inefficient. The best performing commercially available silicon solar panel so far has a power conversion efficiency of only up to 22% [4]. This means that only less than a fourth of the light striking the solar panel is absorbed by the cells due to limitations imposed by various factors including climate conditions and the nature of materials comprising the solar cells. Although, this conversion efficiency is already relatively high compared to other cell types, production cost presents another major difficulty. It takes approximately 14 kW-hours of energy to produce a kilogram of metallurgical grade silicon [5]. Silicon panels also tend to be rigid and bulky, making them only suitable for large-scale application.

The development of new materials such as perovskite, one of the many types of materials classified under the third generation of photovoltaics, has the potential to overcome the limitations of the previous breeds of solar cells.

Researchers from the Australian National University achieved an efficiency of 26% for perovskite [6], merely eight years since its feasibility as photovoltaic material was established. It is a promising material because achieving the same efficiency took 40 years of R&D in the case of silicon.

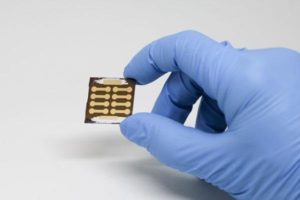

In addition, perovskite cells can be manufactured at a third of silicon cell production cost. Also, perovskite cells can be prepared in different forms such as a dye for thin films or spray-on, making them lighter, more portable, and readily installable in smaller spaces such as windows.

The enormous decrease in energy payback time (EPBT), which is the time it will take for the energy invested on fabricating the solar cell to be generated by the solar cell itself, is a useful indicator of perovskite’s potential. Perovskite cells may reduce EPBT to just two to three months [7], a significant improvement from an average of three to four years for first generation solar cells.

However, the advantages offered by perovskite cells come with several challenges. The primary materials currently being used (e.g., organic-inorganic lead) are generally toxic and can cause harmful effects on the environment when mass produced. Like most electronic devices, the perovskite cell is very prone to damage when exposed to moisture. Shelf life is also tremendously affected by fluctuating temperatures and extreme weather conditions. These limitations make it a significant challenge to increase perovskite’s scalability, a general requirement for industrial applications and commercial use.

Considering the overwhelming progress in perovskite research, efforts have been made to address these concerns. Research at the University of Oxford focuses on replacing lead in the fabrication process and using halide double perovskites instead of lead halides. Holst Centre, a Dutch research company, is also working on improving cell durability through waterproofing by encapsulation. The team is using similar techniques previously employed for thin-film organic cells.

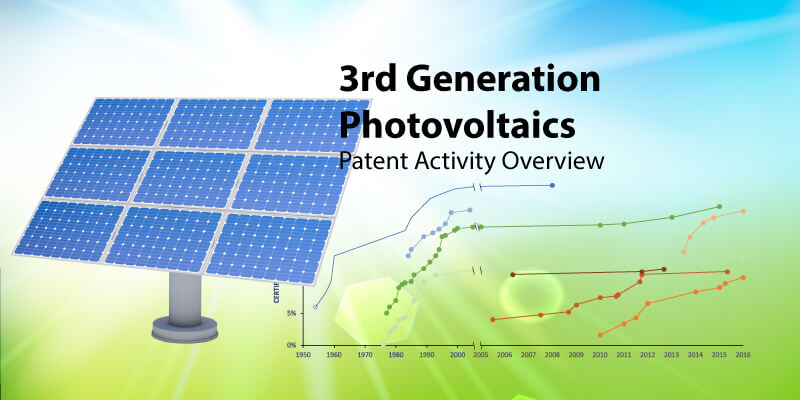

Our work at Parola Analytics provides further insights on patents and academic publications related to third generation solar cell. Our work shows that both patent filings and academic publications have been growing in the past 10 years, with the total number of patent filings almost double that of those covering first and second generation solar cells. China significantly contributes to both patents and academic publications.

The continuous research efforts and fast-paced progress tell us that it may not take several decades for third generation solar cells such as perovskite to be highly commercialized. The applications of an inexpensive material of such small form factor are endless, and may potentially disrupt current renewable energy generation and power storage technologies.

Parola Insights: 3rd Generation Photovoltaics Patent Activity Overview